Exactly How an Optical Fibre Diameter Analyser Improves Top Quality Control in Fibre Production

The assimilation of an Optical Fibre Diameter Analyser into Fibre manufacturing procedures represents a considerable innovation in quality assurance methodologies. By offering real-time, specific dimensions of Fibre sizes, this innovation addresses the vital requirement for uniformity in manufacturing standards. With its capacity to swiftly identify deviations and punctual corrective actions, the analyser not just improves item reliability but also contributes to general functional performance. As sectors significantly prioritize high quality and compliance, recognizing the complete effect of such developments becomes essential. What ramifications could this have for the future of Fibre manufacturing?

Relevance of Fibre Diameter Dimension

Exact dimension of Fibre Diameter is important in the area of optical Fibre technology, as it directly influences the efficiency and dependability of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying capacity, depletion, and total transmission performance. Accuracy in gauging Fibre Diameter guarantees that the optical residential or commercial properties are kept within defined tolerances, which is important for ideal signal stability.

Variations in Fibre Diameter can cause increased losses due to scattering and modal diffusion, influencing the top quality of data transmission. In high-speed interaction systems, such disparities can cause substantial destruction of signal high quality, bring about data errors and decreased performance. Additionally, consistent Fibre Diameter is necessary for compatibility with adapters and splicing technologies, which are essential parts of Fibre optic networks.

Quality assurance procedures in Fibre manufacturing greatly rely upon accurate Diameter measurements to make certain compliance with sector standards. By implementing robust measurement strategies, suppliers can enhance product integrity, lessen waste, and enhance overall system performance. Hence, the relevance of Fibre Diameter dimension can not be overstated, as it offers as a keystone in the improvement of optical Fibre technology and its applications in contemporary interaction networks.

How the Analyser Works

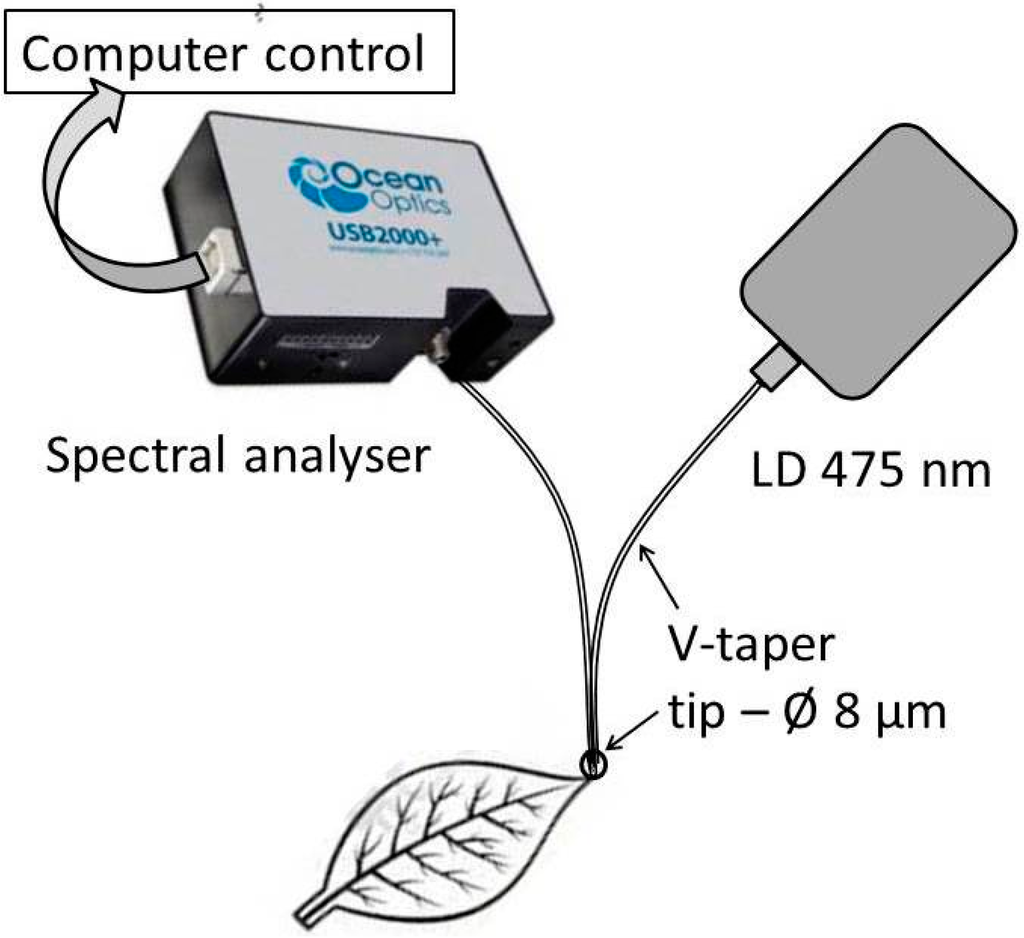

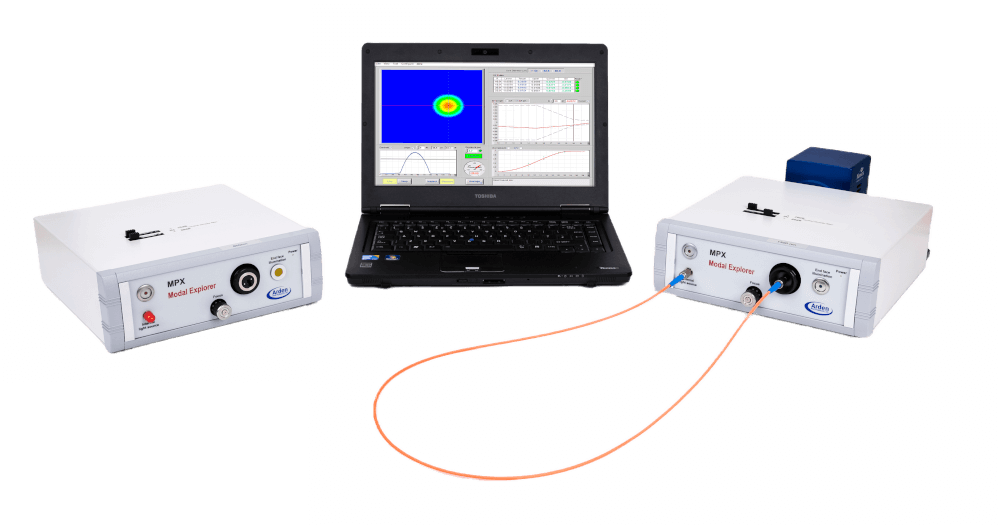

The efficient measurement of Fibre Diameter depends on sophisticated logical strategies that make sure accuracy and reliability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser uses a combination of laser technology and progressed image handling algorithms to accurately evaluate the Diameter of fibres as they are generated

Initially, a laser beam is guided at the moving Fibre, producing a cross-sectional shadow. The analyser records this shadow making use of high-resolution cameras positioned tactically along the assembly line. The caught photos are then processed in real-time to establish the Fibre's Diameter with extraordinary accuracy.

The system makes use of advanced algorithms that represent numerous variables, consisting of variations in light strength and ecological conditions, to improve measurement dependability. It can identify minute modifications in Diameter, such as variations that may occur during the production process.

In addition, the analyser can handling several fibers at the same time, enhancing throughput without compromising accuracy. By providing immediate feedback on the Diameter, the Optical Fibre Diameter Analyser plays an important role in preserving rigorous top quality control requirements, making sure that the end product fulfills sector specifications and client needs.

Benefits of Real-Time Tracking

While typical techniques of monitoring Fibre Diameter often include lengthy post-production checks, real-time surveillance significantly boosts the effectiveness and quality of optical Fibre production. optical fibre diameter analyser. This positive strategy allows producers to identify inconsistencies in Fibre Diameter as they occur, rather than waiting till production is full to assess top quality

By constantly determining the Diameter during manufacturing, manufacturers can guarantee that the fibres satisfy rigorous specs, causing lowered variability and enhanced consistency. Real-time tracking additionally allows instant restorative activities to be taken, decreasing waste and stopping malfunctioning fibres from going into the supply like this chain.

Furthermore, this innovation promotes enhanced data collection and evaluation, supplying understandings right into manufacturing fads and prospective locations for renovation. Such data-driven decision-making equips manufacturers to optimize procedures and maintain high requirements of high quality control.

On top of that, real-time tracking promotes a society of constant improvement within the manufacturing environment. Workers are much more involved when they can see the influence of their job in real-time, leading to heightened responsibility and a dedication to quality. Overall, the implementation of real-time tracking systems in optical Fibre production converts to superior item quality and raised customer fulfillment.

Effect On Manufacturing Performance

Executing optical Fibre Diameter analysers substantially boosts manufacturing efficiency by improving the manufacturing process. These gadgets assist in continual tracking of Fibre Diameter, read enabling makers to identify deviations in real-time. By recognizing inconsistencies without delay, assembly line can be adjusted quickly, minimizing downtime and lowering the probability of producing faulty items.

Moreover, the integration of these analysers right into the manufacturing workflow makes it possible for far better source allocation. With precise Diameter measurements, operators can maximize product use, making certain that sources are not thrown away on problematic fibres. This accuracy also adds to less remodel and ditch, ultimately decreasing production expenses.

The automation offered by optical Fibre Diameter analysers reduces reliance on hand-operated evaluations, which are susceptible and commonly taxing to human mistake. Because of this, staff members can focus on even more critical tasks, enhancing overall efficiency.

Furthermore, the data produced from these analysers can educate process renovations and help with far better decision-making. By evaluating trends in Fibre Diameter variants, manufacturers can carry out proactive measures to improve production techniques and maintain regular top quality. In recap, optical Fibre Diameter analysers play a vital role in increasing production efficiency, causing better result and enhanced earnings.

Situation Studies and Success Stories

Throughout numerous fields, instance researches highlight the transformative impact of optical Fibre Diameter analysers on production processes. One famous example is a leading telecoms business that faced challenges with irregular Fibre sizes, causing enhanced rejection prices. By incorporating an optical Fibre Diameter analyser, the business attained real-time tracking of Fibre dimensions, resulting in a 30% decrease in flaws and considerable cost financial savings.

In addition, a research study organization concentrating on sophisticated materials utilized optical Fibre Diameter analysers to improve their experimental processes. The analyser's ability to provide thorough understandings right into Fibre consistency enabled the development of innovative materials with enhanced performance features.

These success stories underscore the essential role of optical Fibre Diameter analysers in boosting top quality control, enhancing manufacturing performance, and driving advancement throughout diverse industries.

Verdict

Finally, the Optical Fibre Diameter Analyser plays a critical role in boosting quality control within Fibre manufacturing. By giving accurate, real-time dimensions and helping with prompt corrective activities, this technology substantially lowers variability and lessens waste. The implementation of such sophisticated tools promotes a society of constant enhancement and functional effectiveness, inevitably making sure conformity with sector requirements and preserving competitiveness. As demonstrated with various study, the analyser confirms essential for achieving premium product top quality in Fibre manufacturing.

The application of optical Fibre Diameter analysers allowed for stringent high quality control, guaranteeing that the produced fibers satisfied exacting sector criteria.In final thought, the Optical Fibre Diameter Analyser plays an essential duty in improving quality control within Fibre manufacturing.