Exploring the Art of In-Mold Decorations: A Comprehensive Take A Look At Developments and approaches

In the realm of production, the integration of creativity and functionality has long been a pursuit for perfection. When it involves in-mold decorations, a marital relationship of creative thinking and precision arises to redefine the opportunities of design. From the advancement of techniques to the development of cutting-edge materials, the landscape of in-mold designs is a canvas where technology flourishes. As we dig right into the methods and developments shaping this field, a deeper understanding of the complex procedures and infinite potentials waits for.

Evolution of In-Mold Decoration Techniques

The evolution of in-mold decoration techniques has significantly advanced the visual possibilities and efficiency of item decor in making procedures. In the past, standard techniques of embellishing products typically included post-processing steps that were taxing and included intricacy to the assembly line. Nevertheless, with the introduction of in-mold decoration (IMD) strategies, makers can now perfectly integrate decorative elements straight right into the molding process.

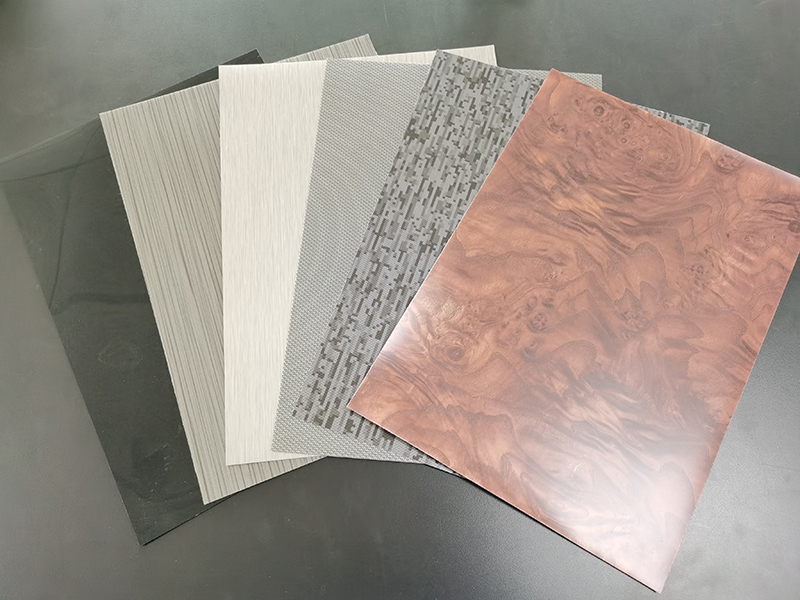

Among the crucial improvements in IMD techniques is the capability to achieve detailed styles with outstanding detail and clarity. By making use of innovations such as high-resolution printing and advanced mold surface treatments, manufacturers can develop visually magnificent designs on products varying from consumer electronic devices to automotive components. Additionally, IMD strategies have made it possible for the consolidation of appearances, surfaces, and shades that were previously tough to achieve with typical decoration approaches.

Advanced Materials and Technologies

Progressing the forefront of development in production, the integration of advanced products and modern technologies has reinvented the landscape of in-mold decor techniques. Advanced materials such as unique polymers and nanocomposites offer improved longevity and aesthetic residential properties, permitting for vivid colors and elaborate styles to be integrated flawlessly right into the last item. These materials also offer enhanced resistance to environmental aspects like UV radiation and chemicals, raising the long life of the decors.

Technical advancements, such as digital printing and 3D surface area texturing, have further expanded the opportunities in in-mold decors. Digital printing enables high-resolution graphics to be straight related to the mold and mildew surface area, causing exact information and sharp pictures. On the other hand, 3D surface texturing techniques create responsive results that improve both the sensory and visual appeal of the decorated items.

The harmony in between sophisticated materials and technologies not just boosts the appearances of in-mold decors however likewise increases efficiency in the production procedure, making it much more eco friendly and cost-effective (In-Mold Decorations). This assimilation leads the method for unlimited creative opportunities in the world of in-mold decoration

Intricate Style Possibilities

Exploring the world of in-mold decors introduces a world of elaborate design possibilities that press the limits of creative thinking and accuracy. Producers are no more restricted to straightforward patterns or styles; instead, they can currently attain extremely detailed and intricate decorations on their products. In-mold decoration strategies permit the consolidation of great lines, complex structures, and vibrant shades that were previously challenging to accomplish with other methods.

Among the essential advantages of in-mold decorations is the capacity to produce 3D results, including depth and realistic look to the style. This technique opens a wide variety of imaginative possibilities, making it possible for producers to replicate all-natural products like wood grain or marble with astonishing precision. Additionally, in-mold designs can be used to produce unique surfaces such as shiny textures or metallic results, enhancing the total aesthetic charm of the item.

Additionally, in-mold designs offer exceptional accuracy, guaranteeing uniformity in design across a big manufacturing run. This level of detail and precision is essential for markets where branding and layout integrity are vital, such as in the auto or consumer electronics markets. Overall, the elaborate style opportunities afforded by in-mold decorations continue to reinvent the means items are decorated and developed in different sectors.

Sector Applications and Innovations

Structure upon the intricate layout possibilities assisted in by in-mold decorations, view publisher site numerous industries are using innovative applications to boost product looks and functionality. Furthermore, the consumer electronics sector is leveraging in-mold decorations to generate sleek and contemporary tools with seamless styles that integrate switches and presents into the item surface. By accepting in-mold decorations, these sectors are setting new requirements for item design and looks, giving consumers with ingenious and aesthetically striking items.

Future Trends in In-Mold Decorations

Welcoming advancing modern technologies and style methods, the world of in-mold decorations is poised to witness considerable changes and innovations in the close to future. One of the key future trends in in-mold designs is the boosting assimilation of clever modern technologies. This consists of the incorporation of features like interactive displays, LED lighting, and even smart sensors directly into the shaped components. Such innovations not just boost the aesthetic allure of the items however likewise add practical value, making in-mold decorations much more than just a design element.

Moreover, sustainability is coming to be a critical emphasis in the field of in-mold decors. Makers are exploring environmentally friendly materials and procedures to decrease ecological effect while maintaining high-grade requirements. This trend lines up with the growing customer demand for lasting products, pressing the industry in the direction of more eco conscious techniques.

Furthermore, modification and look at these guys personalization are anticipated to play a considerable duty in the future of in-mold decorations. With innovations in digital printing modern technologies and software capacities, Continued manufacturers will certainly have the ability to provide even more tailored options to fulfill private consumer preferences. This pattern is most likely to drive innovation and imagination in the layout and production processes, giving tailored and distinct items to customers.

Conclusion

In-mold design methods have actually evolved considerably, using innovative materials and technologies that allow complex layout opportunities. These innovations have discovered applications across different sectors, bring about continual advancements and future trends in in-mold decorations. The art of in-mold decorations continues to push limits and produce new possibilities for improving product appearances and capability.

Structure upon the complex style opportunities assisted in by in-mold decors, numerous markets are taking advantage of ingenious applications to raise item looks and performance. Furthermore, the consumer electronics industry is leveraging in-mold decorations to produce streamlined and modern-day gadgets with seamless designs that integrate switches and presents right into the product surface. By welcoming in-mold decors, these markets are setting brand-new criteria for product design and visual appeals, providing customers with aesthetically striking and cutting-edge products.